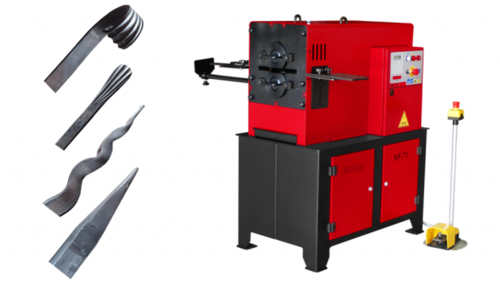

End Wrought Iron Machines

Product Details:

- Usage Industrial

- Body Material Steel

- Product Type End Wrought Iron Machines

- Color Red

- Voltage 230-440 Volt (v)

- Click to View more

End Wrought Iron Machines Price And Quantity

End Wrought Iron Machines Product Specifications

- End Wrought Iron Machines

- Industrial

- Red

- Steel

- 230-440 Volt (v)

End Wrought Iron Machines Trade Information

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- All India

Product Description

The Wrought iron Machine Nargesa NF70 smashes and molds irons up to obtaining the desired shape depending on the mold design. It forges arrow ends or lances of different kinds, flat, pyramidal, etc. It also makes baluster extremes to accomplish nice ornamental parts by changing the die. It forges and smashes balusters in the middle to make different designs.

All Nargesa products are according to the CE regulations for the manufacturing of industrial machinery.

Technical features

Digital screen.

Turns programmer.

Rotation speed: 20 rpm.

Adjustable back gauge.

With standard accessories wrought ends, flat ends, striated and pyramidal ends can be made. (See STANDARD TOOLING below).

OPTIONAL ACCESSORIES (See below) If the customer asks for it, we make molds under request.

Engine power: 5.5 KW/ 7 CV (HP).

Three phased tension: 230/400 V.

For other tension or single phased machines, please ask the manufacturer.

Palletized lower bench to easily move the machine up to its working place or storage.

The machine is sent completely mounted.

Packaging with a wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

Optional: Complete wooden packaging with fumigated wood NIMF15.

ADVANTAGES:

- Easy handling: Any worker is able to carry out this job, even without any previous preparation.

- Readiness: Thousands of parts can be made in a sole working day.

- Value and prestige: There are few craft men who can make this kind of wrought jobs.

- Sales: Possibility of selling parts with the forged extremes to different companies or steel stores.

All or products are manufactured in our facilities in Spain. The hydraulic and electrical components are all standard from the best leading European trademarks, with technical assistance all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Talleres GAMOR, S.L.

Ind. Asteasu Zona E Pab.73-74,

20159 Asteasu Guipuzcoa, Spain

|

GA-MOR MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |