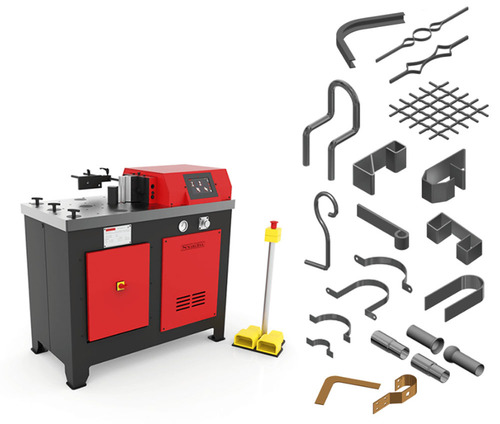

Horizontal Press Brakes PP200CNC model

Product Details:

- Height 1130 Millimeter (mm)

- Length 1180 Millimeter (mm)

- Color Red

- Usage Bending

- Weight 625 Kilograms (kg)

- Size 1180 X 660 X 390

- Width 390 Millimeter (mm)

- Click to View more

Horizontal Press Brakes PP200CNC model Price And Quantity

- 1 Piece

- 1428491 INR/Piece

- 1000.00 - 10000.00 INR/Piece

Horizontal Press Brakes PP200CNC model Product Specifications

- Red

- 1180 Millimeter (mm)

- 1130 Millimeter (mm)

- Bending

- 625 Kilograms (kg)

- 1180 X 660 X 390

- 390 Millimeter (mm)

- Horizontal Press brake

Horizontal Press Brakes PP200CNC model Trade Information

- Ex works Bangalore

- Cheque

- 1 Piece Per Week

- 10 Week

- Contact us for information regarding our sample policy

- Wooden box

- Middle East Asia

- All India

- CE

Product Description

This equipment has been produced from 60 cm thick steel monoblock that has been welded and mechanized. Notable for its sturdy construction, this machine is appreciated for its high output. This system has several advantages that include:

Ease of handling: Available in fully assembled structure, this machine can be attached to the power sources easily for trouble free starting.

Multi-purpose role: This machine is offered with numerous additional tools (go through the bottom of the page in optional tooling section).

Ease of handling of tooling: With this machine, anyone can himself or herself produce punches and dies.

This machine can be used for folding jobs without affecting dies and punches.

Offered equipment can be used for handling of metal sheets and flat bars in closed shapes. This high performance system deserves praise for its advanced features.

The operator can change its dies, punches and other tools without any delay. It requires hardly 30 seconds to change these components.

STANDARD TOOLING: This machine is equipped with complete set of 4Vïs folding die ( mentioned in the bottom of the page of standard accessories).

Technical Caracteristics of the Horizontal Hydraulic Press Machine

ï 20.000 Kg (200 KN).

ï 10 mm/s.

ï 35 mm/s.

ï 250 mm.

ï 0,05 mm.

ï 600x1170 mm.

ï 950 mm.

ï Manual or Automatic.

ï ï ï ï ï 2.2 KW/3 HP a 1400 r.p.m.

230/400 V three-phased.

ï 9/5 A.

ï 50 to 215 Kg/cm2.

ï 7,5 litres/minute.

ï 27 litres.

ï ï 760x1174x1150 mm

ï Weight: 625 Kg.

Consists of pallet equipped lower bench to simplify its relocation process to storage or working section of factory

This machine is packed in wooden pallet which is covered with three layers of cardboard for its safe transportation by sea freight.

This machine is delivered in assembled form.

Our products have been produced in our well equipped production unit in Spain. Electric and hydraulic parts of our equipments are of premium quality and these belong to renowned brands like Schneider Electric, Rexroth, LG, Pizzato, Telemecanique, Roquet and so on.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Horizontal Press Brakes' category

Talleres GAMOR, S.L.

Ind. Asteasu Zona E Pab.73-74,

20159 Asteasu Guipuzcoa, Spain

|

GA-MOR MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese